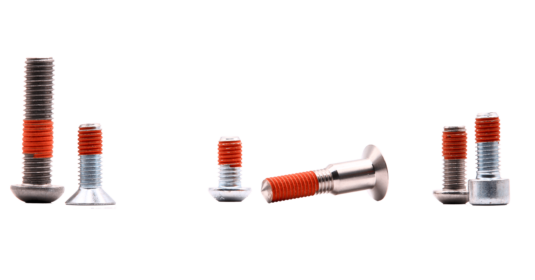

What is SOPRIFIX SO22R? An orange braking product

SO22R is a microencapsulated adhesive designed to brake threaded fasteners and seal them under certain conditions. The SO22R product, deposited in our factories, remains inert until assembly. As soon as the product is activated after screwing, the resin polymerises and ensures the braking and sealing of your assemblies.

Application of SO22R to fasteners

Fasteners coated with SO22R hold your assemblies in place despite vibrations and provide braking and sealing for various applications: screws, threaded parts,…

Characteristics of Soprifix SO22R

| Type | Color |

|---|---|

| Epoxy microencapsulated Resin | Orange |

Properties of assembled fasteners

| Screw-in torque (Cfv) | Breakaway torque (Cdec) | Prevailing off-torque (Cfd) | Temperature range | Cure time at 23°C | Coefficient of friction |

|---|---|---|---|---|---|

| 0.55 N.m | 30 N.m | 22 N.m | -54°C / +150°C | 72 hours (100%) |

0,14 zinc organic 0,19 zinc plate |

Note : Tests are conducted on M10x1,5 class 10.9 zinc organic finish bolts and M10x1,5 zinc nuts. Performance may vary depending on fastener size and finish.

Resistance to fluids

| Temperature | % Initial Strength | |

|---|---|---|

| SW30 Synthetic oil | 150°C | 88 |

| Brake fluid | 150°C | 94 |

| 50/50 coolant | 100°C | 109 |

| Transmission fluid | 150°C | 104 |

| Gasoline | 23°C | 100 |

| Gasoline / Ethanol | 23°C | 108 |

| 15W40 Lubricant | 150°C | 110 |

| Cyclic aging | -40 to +50°C | 261 |

| Heat age | 150°C | 84 |

Note : The tests were conducted on M10x1,5 zinc organic finish bolts and a zinc plate nuts. Assembled fasteners were aged at the temperature listed above for 168 hours and allowed to cool to room temperature before breakaway test.

Service life and storage

Coated fasteners with SO22R product are recommended to be stored for 2 years before final assembly in a cool and dry location with temperatures between -10°C to +35°C. Optimal storage is 25 +/-4° C with 50% or below relative humidity.

General Information

The data contained on this data sheet is representative of the performance of fasteners coate with SO22R product. However, we recommend to conduct preliminary tests to determine suitability for your application.