What is Pellet & Strip?

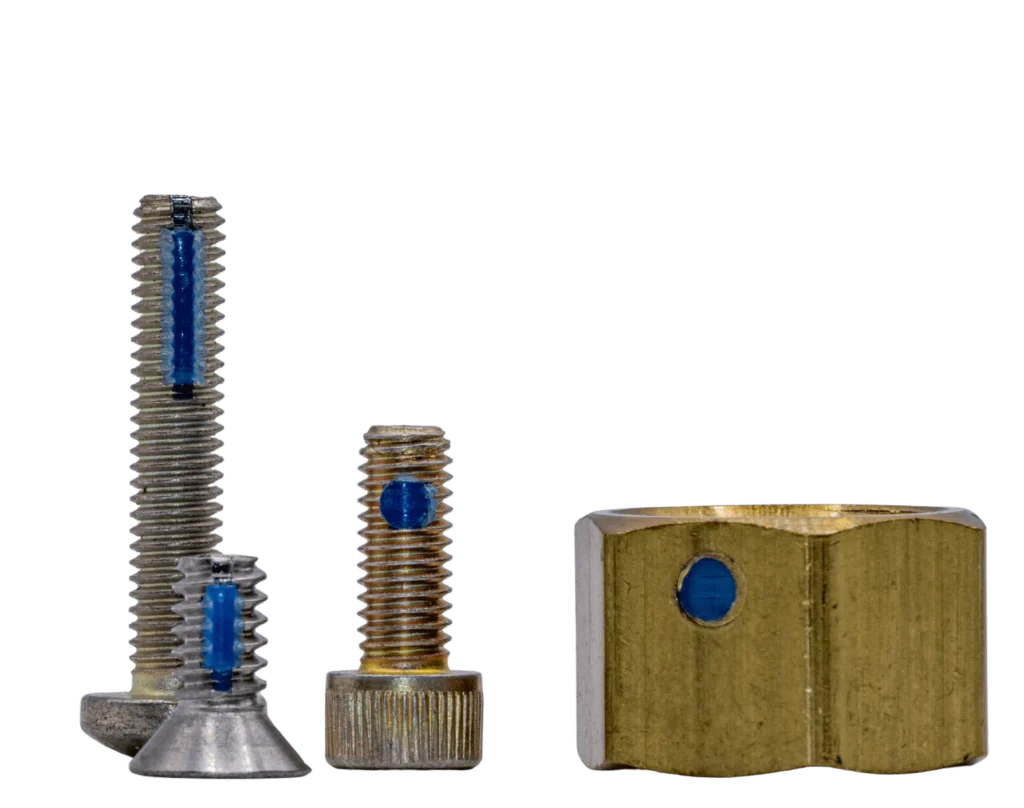

The Pellet & Strip is a braking process consisting of Nylon permanently inserted into the thread of the fastener:

– The ‘Pellet’ consists of a nylon plug inserted into a hole drilled in the thread.

– The Strip is a piece of nylon inserted into a groove machined into the thread.

When the Pellet & Strip is engaged, the compressed excess thickness of Nylon creates radial tension in the assembly, resulting in metal-to-metal contact between the components. The result of this contact is positive resistance to vibration and loosening.

Nylon has excellent memory characteristics, so this braking product can be reused several times.

The Pellet & Strip is approved to MIL-DTL-18240F and NASM 25027 standards.

Applying Pellet & Strip

Pellet & Strip can be applied to the internal and external threads of fasteners in a variety of sectors:

- Automotive: To secure critical components subject to vibration.

- Aerospace: Used in demanding environments to guarantee safety.

- Electronics: To prevent loosening in sensitive equipment.

- Industry: Suitable for machines and equipment subject to constant vibration.

The advantages of braking with Pellet & Strip

-Reusable/adjustable

-Exceptional resistance to vibration

-Resistant to lubricants, fuels, hydraulic fluids and most commercial solvents

-Can be applied to any size or thread configuration of a part

-Meets or exceeds IFI, DIN and major OEM specifications

Technical data

| Product | Color | Operating temperature | Service life | Fixed insert | Dimensions |

|---|---|---|---|---|---|

| Nylon | Blue/Red | -56°C to 121°C | Infinite | Immediate locking | From M1.2 |

Specifications

| Manufacturer | Specifications |

|---|---|

| Ford |

ES-21000-S100 ESN-800499-S195 ES-21002-S100 ES-21006-S100 |

| IFI |

IFI-100/107 IFI-155 IFI-555 |

| DIN | DIN 267 Part 15 |

| Other | ANSI.B18.16.1M |